An inaccurate issue assertion - probably the most essential part of conducting productive failure investigations is defining the particular problem in obvious conditions. Failure to do so will result in employing a corrective action which may not deal with The rationale with the failure;

Sample is often inoculated because of the testing laboratory mainly because of the need to have for preprocessing actions for membrane filtration.

A prompt evaluation of all suitable data concerning aseptic manufacturing since the previous successful APS. The result from the evaluation really should include things like a possibility assessment of probable sterile breaches in batches produced Because the previous successful process simulation.

Risk assessment is likewise an integral Component of the investigation process. The extent of hazard for the affected person or consumer ought to be determined and correct motion taken. It is vital to notice that containment motion is really a fluid process as the extent of data will improve eventually.

When conducting a root bring about failure Evaluation (RCFA), some a number of impressive methodologies and techniques is often leveraged to uncover the underlying causes of failures. Permit’s discover a number of the most often utilized RCFA resources:

Aseptic relationship is done in a very Grade C or Quality B surroundings instead of Quality A because of an absence of method or operator recognition.

Comments or questions about doc information cannot be answered by OFR employees. You should tend not to present private info or own info.

The course of action must state what benefits are to generally be claimed. If an assignable cause is discovered, the first success needs to be invalidated as well as the retest outcomes reported.

USP (eighteen) could be the marketplace common for product sterility testing. In an effort to assistance the global trade of pharmaceutical agents for overall health treatment advancement and affected person care, and to ensure the universal security of those products, quite a few parts of the USP have already been harmonized with the corresponding texts of the eu Pharmacopeia and/or maybe the Japanese Pharmacopeia (twenty, 21). Highlights with the ways of USP are summarized in Desk one.

Confirm that here the Manage and checking functions display which the process is at this time working in accordance Using the DMR. Sterilization parameters which can must be monitored and controlled consist of: time, temperature, pressure, load configuration, and humidity. Quite a few of those parameters could need checking and Handle prior to, throughout and immediately after sterilization processing (e.

When the pursuits and time points are already documented, it truly is important to establish a relationship among these things to do and any situations of contamination or failures which will have happened. By analyzing the data, brands can detect possible components that contributed into the failures.

While in the immediate inoculation strategy, a test sample is right inoculated while in the lifestyle media using a sterile pipette or syringe. In case the test sample can be an antimicrobial agent, it is actually neutralized by incorporating suited inactivating brokers to your medium.

If the root reason for the failure is set then read more the trigger is regarded as assignable cause as well as media fill testis repeated With all the corrective and preventive steps.

Most corporations keep a "Master Listing" in the presently authorised paperwork. This record might be confirmed from the DMR and brought to your shop floor to match Together with the currently available files.

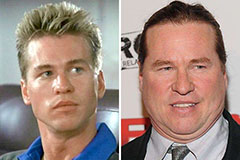

Val Kilmer Then & Now!

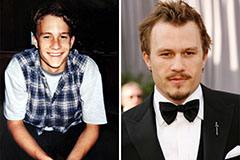

Val Kilmer Then & Now! Heath Ledger Then & Now!

Heath Ledger Then & Now! Melissa Joan Hart Then & Now!

Melissa Joan Hart Then & Now! Rachael Leigh Cook Then & Now!

Rachael Leigh Cook Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!